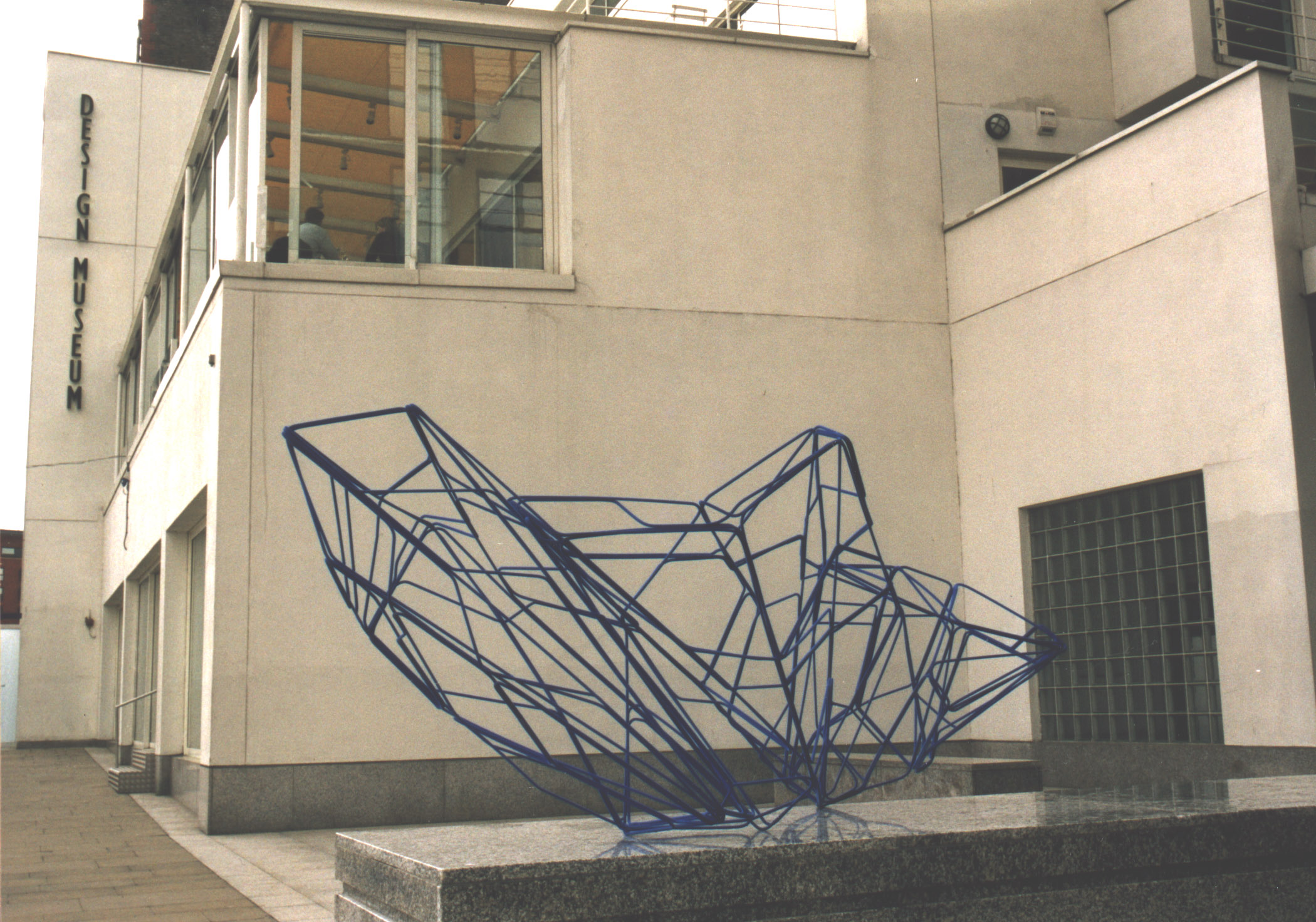

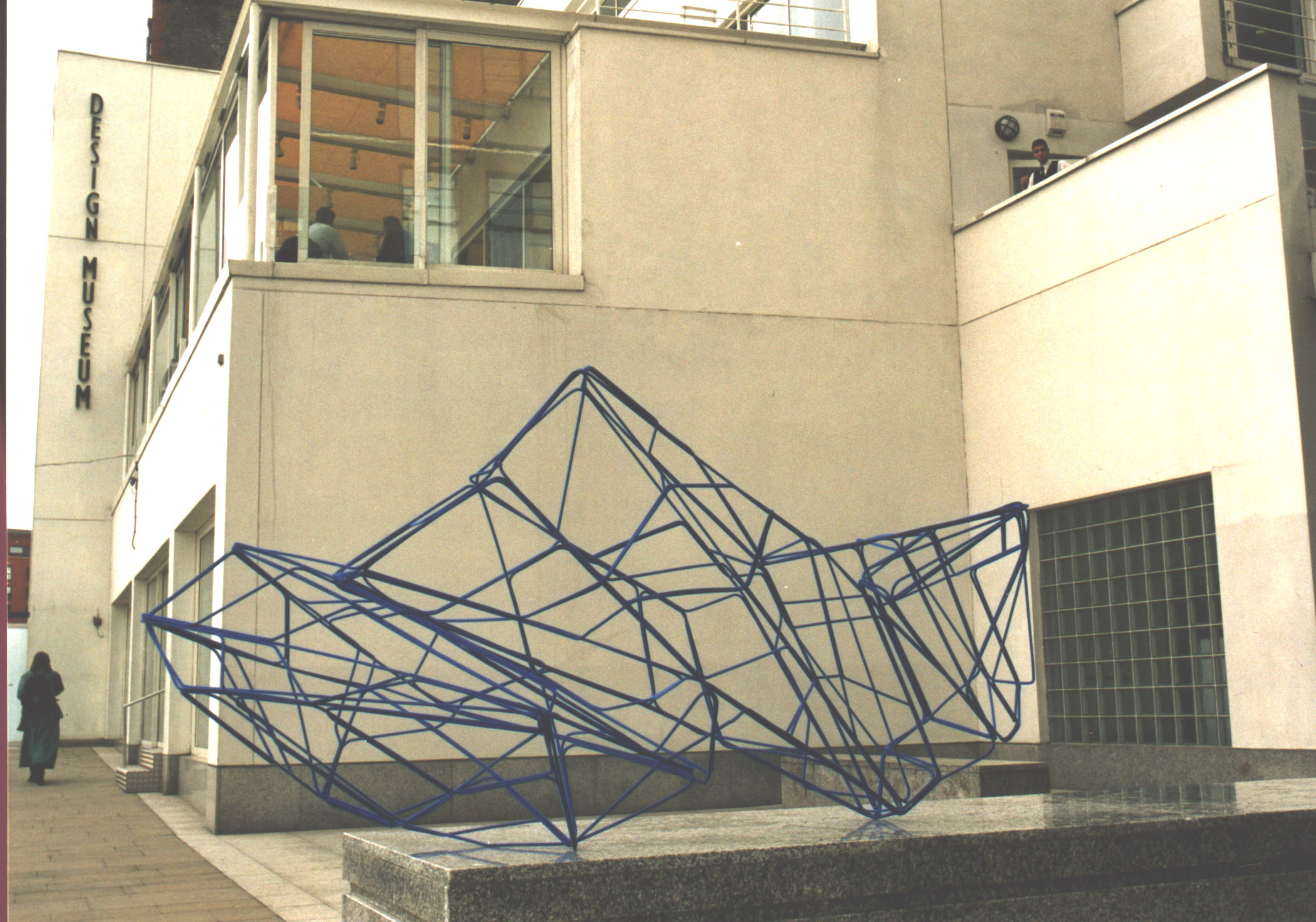

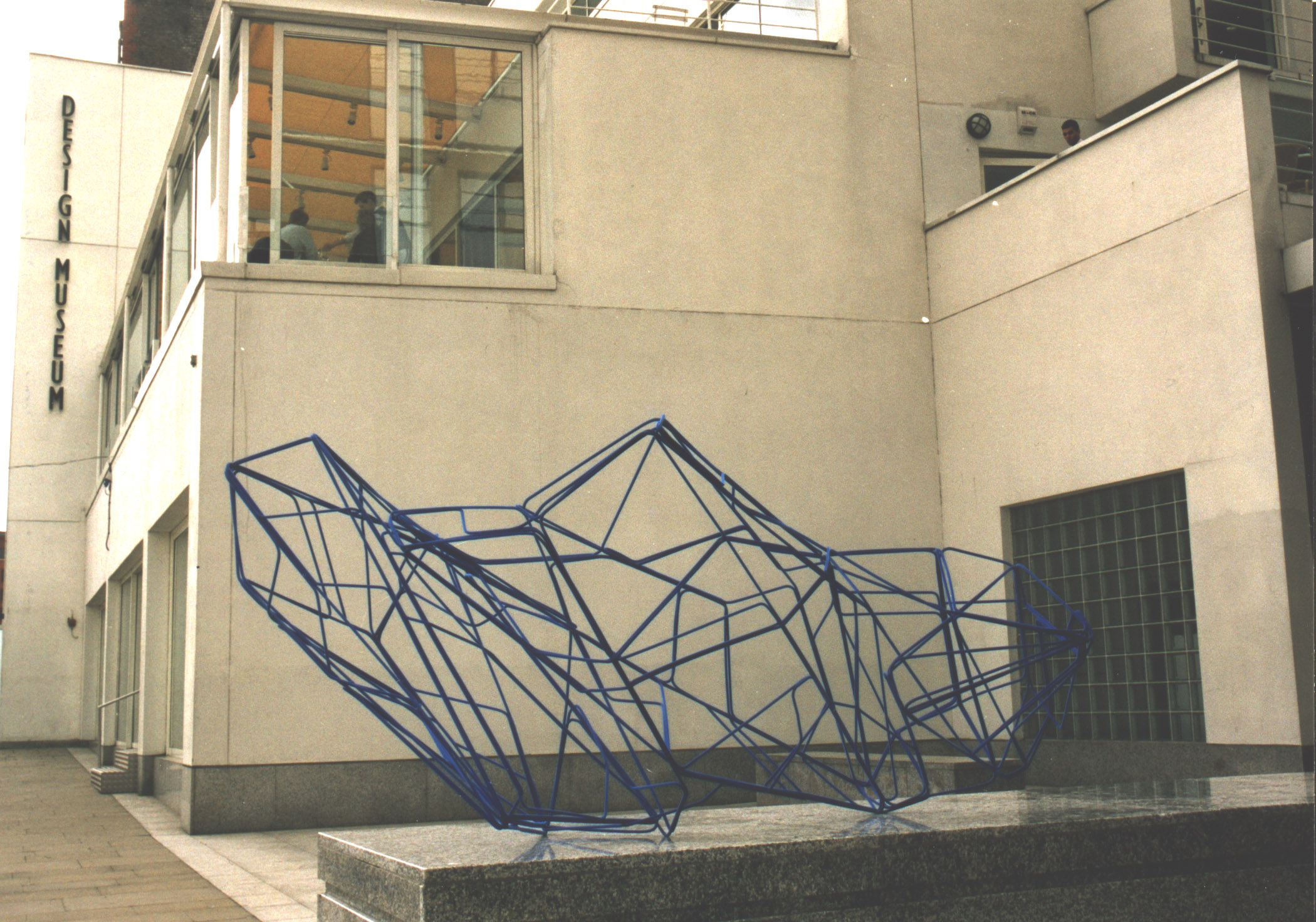

Tumbleweed, London

Commissioned by Archilab; Purchased by Fonds Régional d’Architecture Contemporaines (FRAC)

Urban Public Art

OCEAN UK: Nate Kolbe, Tom Verebes

Adams Kara Taylor Consulting Engineers, Hanif Kara

Exhibitions:

- DRLTENPOINTZERO, Architectural Association, February-March, 2008

- What We Call Progress, Gasworks Gallery, London, 2000

- Archilab 2000, Orléans, France, 2000

- Architecture Expérimentale 1950-2000: La Collection du FRAC Centre, Orléans, France, 2003

Publications:

- Verebes, T., (2008). AADRL Documents 2: DRL TEN, A Design Research Compendium. (Obuchi, Y., Schumacher, P., Spyropoulos, T., Verebes, T., Eds.). London: AA Publications. MAV PACA (2007). “Architectures computationnelles”. Paris: Editions HYX

- Brayer, M-A., Migayrou, F., Eds. (2003). Architecture Expérimentale 1950-2000: La Collection du FRAC Centre. pp. 346-347.

- Migayrou, F., Brayer, M-A. (2000). “Archilab Orleans 2000”. Le Plessis-Robinson, France: Blanchard. pp. 178-185.

- Stavro, A., Ramos-Pinto, A., (2001). “Digital Hybrids”, Lab 02, Summer 2001. (Stavro, A., Ramos-Pinto, A., Eds.). London: editorial Lloyd. pp. 126-129.

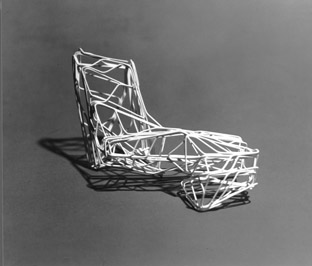

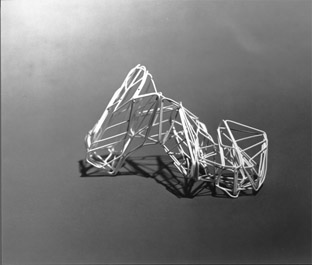

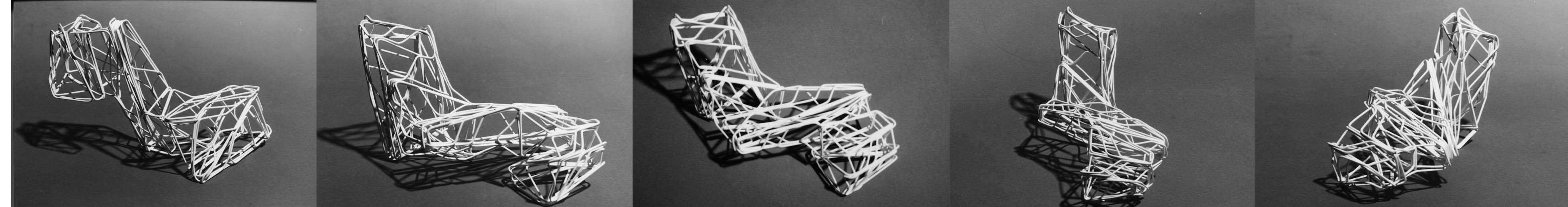

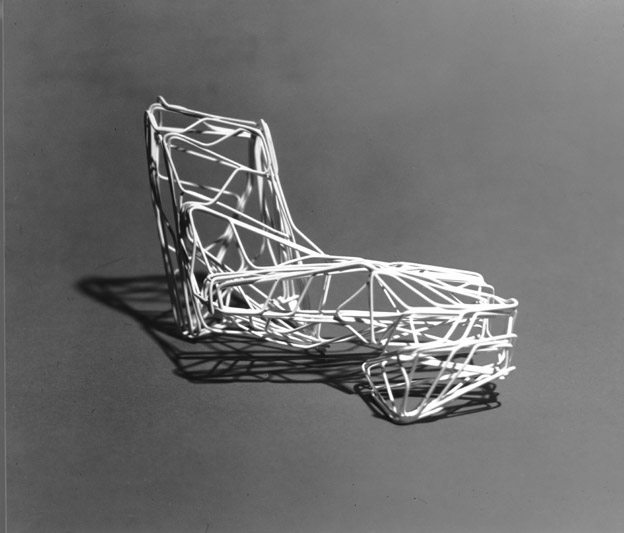

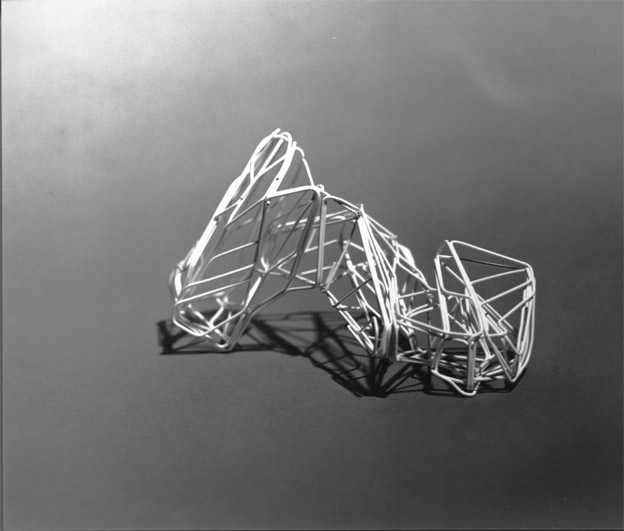

A broad selection of 20th century furniture sections are sampled and abstracted as a genetic code in the generation of Tumbleweeds. Tumbleweeds are topological constructs, in that they can be configured in a variety of sizes, maintaining its coherent geometrical relationships. The organisation of the tubes follow three directional orientations that converge in structural laminations, and re-orient to shift to adjacent laminated tubes or rods. The surfaces of Tumbleweeds provide opportunities to be infilled with foam, or sheathed with a loose inflatable skin, or wrapped in a taught skin. The piece defies conventional codes of utility of furnishing objects via the abstraction of occupational certainty, and the lack of a defined orientation to the ground. Tumbleweeds roll with force exerted by the user, with differential states of stability, as the user is always on the verge of finding new ways to use the object. The first production prototype was manufactured with 200m of 6mm extruded solid steel rods, welded as parallel bundles, and sprayed with electric blue flocking.